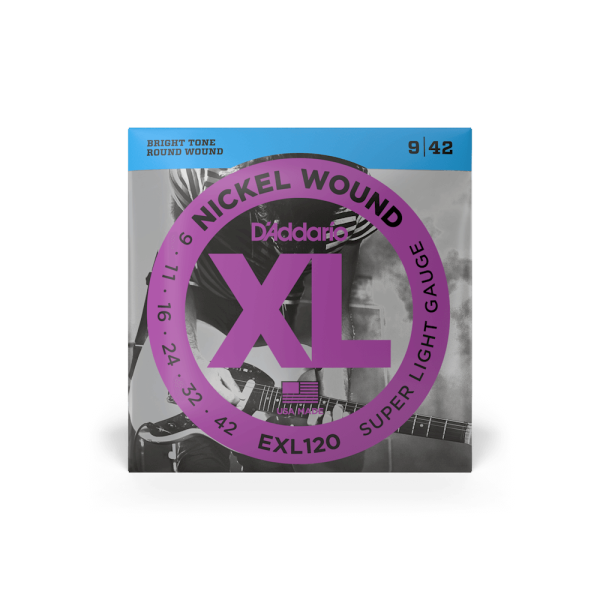

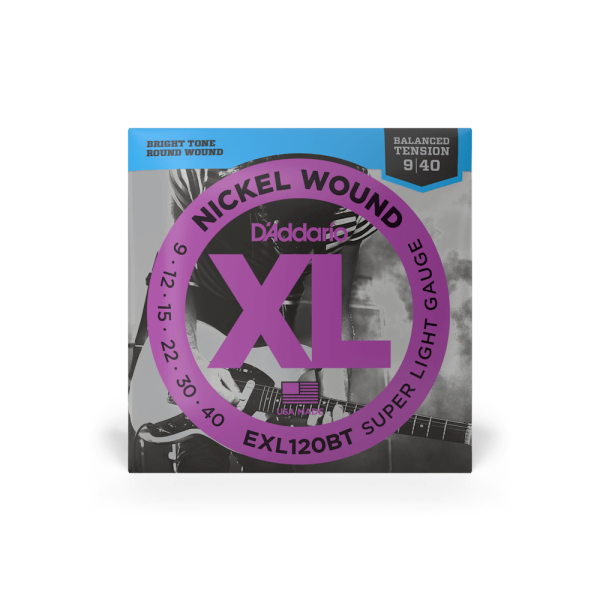

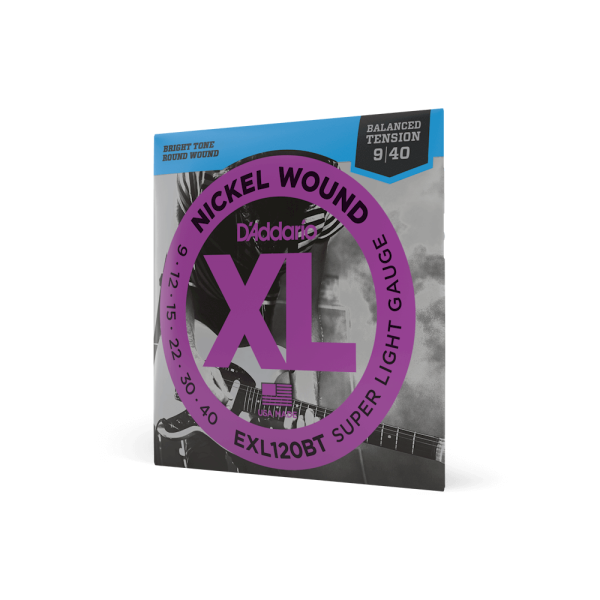

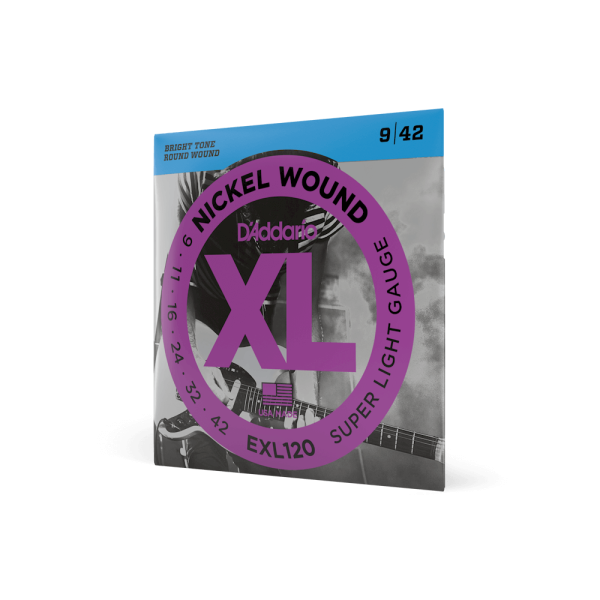

D Addario XL Carbon Steel 09-40 Super Light Electric Guitar Strings Set with Nickel Plating (Balanced Tension set Available) | EXL-120 EXL120BT Fashion

Description

XL Nickel Wound electric guitar strings are the standard against which all other strings are measured. Our best-belling electric set, XL Nickel has been revered by players everywhere since 1974.

Made with a high carbon steel core and nickel-plated steel wrap wire, XL Nickel strings have a bright, versatile tone, ideal for a wide variety of musical styles. 9-42 Super Light gauge strings are easy to bend and very flexible.

The 09-40 Super Light Balanced Tension set is designed for greater dynamic control and a more consistent feel between strings.

DIAL IT IN. CRANK IT OUT.

XL Nickel Wound, D Addario s most popular guitar strings, are precision wound with nickel plated steel onto a carefully drawn, hexagonally shaped, high carbon steel core. The result—strings with long lasting, distinctive, bright tone and excellent intonation—is ideal for the widest variety of guitars and musical styles.

ROUND, WOUND, AND RESPONSIVE.

ROUND WOUND STRINGS

Round wound strings have the feel and tone that most players are familiar with. This string construction combines the strength of the steel core with the tonal properties of the wrap wire alloy.

WOUND TO PERFECTION 700,000 TIMES A DAY.

STRING WINDING TECHNOLOGY

String winding equipment is designed and built by D Addario s engineering team, guaranteeing a production range of 500,000 to 700,000 strings per day. Digitally-controlled string winding machines ensure productivity, accuracy, and consistency.

SIX SIDES OF STABILITY.

HEX CORE CONSTRUCTION

Precision drawn hexagonal core was pioneered by D Addario. This innovation allows the wrap wire to grip the core for superior dimensional stability, enhanced durability, and precise intonation.

EXACT STANDARDS, EXTRAORDINARY SOUNDS.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

ROUND WOUND STRINGS

Round wound strings have the feel and tone that most players are familiar with. This string construction combines the strength of the steel core with the tonal properties of the wrap wire alloy.

WOUND TO PERFECTION 700,000 TIMES A DAY.

STRING WINDING TECHNOLOGY

String winding equipment is designed and built by D Addario s engineering team, guaranteeing a production range of 500,000 to 700,000 strings per day. Digitally-controlled string winding machines ensure productivity, accuracy, and consistency.

SIX SIDES OF STABILITY.

HEX CORE CONSTRUCTION

Precision drawn hexagonal core was pioneered by D Addario. This innovation allows the wrap wire to grip the core for superior dimensional stability, enhanced durability, and precise intonation.

EXACT STANDARDS, EXTRAORDINARY SOUNDS.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

Round wound strings have the feel and tone that most players are familiar with. This string construction combines the strength of the steel core with the tonal properties of the wrap wire alloy.

WOUND TO PERFECTION 700,000 TIMES A DAY.

STRING WINDING TECHNOLOGY

String winding equipment is designed and built by D Addario s engineering team, guaranteeing a production range of 500,000 to 700,000 strings per day. Digitally-controlled string winding machines ensure productivity, accuracy, and consistency.

SIX SIDES OF STABILITY.

HEX CORE CONSTRUCTION

Precision drawn hexagonal core was pioneered by D Addario. This innovation allows the wrap wire to grip the core for superior dimensional stability, enhanced durability, and precise intonation.

EXACT STANDARDS, EXTRAORDINARY SOUNDS.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

STRING WINDING TECHNOLOGY

String winding equipment is designed and built by D Addario s engineering team, guaranteeing a production range of 500,000 to 700,000 strings per day. Digitally-controlled string winding machines ensure productivity, accuracy, and consistency.

SIX SIDES OF STABILITY.

HEX CORE CONSTRUCTION

Precision drawn hexagonal core was pioneered by D Addario. This innovation allows the wrap wire to grip the core for superior dimensional stability, enhanced durability, and precise intonation.

EXACT STANDARDS, EXTRAORDINARY SOUNDS.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

HEX CORE CONSTRUCTION

Precision drawn hexagonal core was pioneered by D Addario. This innovation allows the wrap wire to grip the core for superior dimensional stability, enhanced durability, and precise intonation.

EXACT STANDARDS, EXTRAORDINARY SOUNDS.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

Precision drawn hexagonal core was pioneered by D Addario. This innovation allows the wrap wire to grip the core for superior dimensional stability, enhanced durability, and precise intonation.

EXACT STANDARDS, EXTRAORDINARY SOUNDS.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

WIRE DRAWING

D Addario s in-house wire drawing machines produce musical instrument wire to our exact specifications. Control over materials, equipment, and quality allows us to deliver high performance products.

Additional Information

| Style | Standard, Balanced Tension Set |

|---|